Interview with Mr.Rajni Patel, Chairman & Managing Director, JMC Paper Tech Pvt. Ltd.

JMC Paper Tech was founded to bridge India’s technology gap in pulp and paper machinery, turning a challenge into an opportunity for world-class engineering.

Paper Desk : What inspired the founding of JMC Paper Tech in 2002? What vision shaped its entry into pulp and paper machinery?

Rajni Patel : JMC Paper Tech was founded in 2002 with a strong conviction that India was ready to emerge as a global engineering hub in the pulp and paper machinery segment. At the time, the Indian industry was heavily dependent on imported machines and technologies, and very few companies were capable of offering complete turnkey solutions. This gap presented both a challenge and an opportunity.

Coming from a family of industrialists and technocrats, I was deeply influenced by the desire to build an organization that embodied engineering excellence, ethical business practices, and long-term value creation. I wanted to demonstrate that world-class machinery could be conceived, designed, and manufactured in India and not merely assembled or imitated. Our founders believed that the future of India’s industrial sector lay in indigenous innovation and global competitiveness. This belief shaped the DNA of JMC from day one: precision engineering, strong technical foundations, uncompromising quality, and a commitment to innovation. In the early years, our focus was on creating reliable, efficient, and cost-effective machinery that could enable Indian paper mills to enhance productivity and reduce dependency on imported equipment. That foundational vision—rooted in engineering excellence and integrity—remains the cornerstone of our identity even today.

PD : How has this founding vision evolved with the company’s global expansion?

RP : Over the past two decades, JMC’s vision has expanded in both scale and ambition. While our core philosophy remains the same, the scope of our work and the markets we serve have grown dramatically. From being a machinery manufacturer, JMC has now evolved into a Globally Recognized EPC Partner delivering complete pulp and paper mill projects across Africa, the Middle East, South Asia, North America, and beyond. Our evolution has been shaped not merely by geographical expansion, but by our drive to become a trusted international technology brand. Today, we execute large turnkey projects—both recycled fiber-based and wood/agro-based pulp mills—bringing together design, manufacturing, process engineering, automation, installation, and commissioning into one integrated solution.

The transformation from a domestic manufacturer to a global engineering house reflects our enhanced capabilities, global credibility, and deep understanding of diverse industrial needs. With successful installations in Uganda, Ethiopia, Kenya, Ivory Coast, South Africa, Bangladesh, Mexico, and Canada, JMC is now synonymous with reliability, precision, and long-term partnership across continents.

PD : What is the scope of machinery and solutions offered by JMC today?

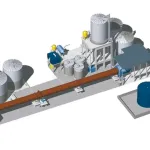

RP : JMC provides a comprehensive range of machinery and turnkey solutions for the pulp and paper industry, covering every stage from fiber preparation to finishing. Our scope includes Advanced Stock Preparation Plants—featuring pulpers, cleaners, screens, approach flow systems—and High-Performance Paper Machines including single-wire, multi-wire, and multi-ply board machines. We manufacture a complete spectrum of Headboxes (hydraulic, dilution-controlled, air-cushion pressurized), Press Sections (single, double, bi-nip, tri-nip, jumbo), Dryer Sections with high-efficiency carbon steel dryers, MG cylinders, Yankee dryers, hood systems, and Size Press/ Film Press systems along with chemical preparation and dosing units. Our capabilities extend to Calendering, Rewinding, Finishing Equipment, and fully Integrated (Wood/ Agro Based) Pulp Mills including continuous/batch cooking, washing, screening, oxygen delignification, and chemical recovery systems. Additionally, we carry out Modernization, Revamps, and Re-engineering projects; undertake Erection, Commissioning, Trial Runs, and Operator Training; and offer On-site Supervision and Baby-Sitting services. Essentially, we function as a Complete EPC Partner from conceptual engineering to production commencement.

PD : What advanced technologies support JMC’s design and manufacturing processes?

RP : Our machinery is designed and engineered using world-class tools and software, including AutoCAD, SolidWorks, AutoCAD Plant 3D, CFD simulations, and Finite Element Analysis (FEA). These tools help us create high-precision digital models, simulate fluid flow, optimize structural performance, and validate critical load conditions even before fabrication begins. On the shop floor, we employ Modern CNC plasma cutting, precision machining, dynamic balancing, welding automation, and high-capacity fabrication systems. Every component undergoes rigorous quality checks, supported by metallurgical testing, NDT, hydro-testing, and third-party inspections.

Technology is not limited to how we design and manufacture equipment—it also drives how we innovate. Our R&D team works continuously to upgrade Headbox uniformity, enhance press section dewatering, optimize energy-efficient stock preparation layouts, improve steel dryer thermal performance, and develop high-speed rewinder designs. These innovations allow customers to achieve higher efficiency, better quality, and lower cost per ton.

PD : Does JMC also innovate and develop optimized components?

RP : Absolutely. Continuous improvement forms a core part of our company culture. We regularly develop upgraded components and re-engineered solutions based on customer feedback and performance studies. Our improvements include enhanced headbox distribution systems for superior CD profiles, energy-saving press section designs that improve dryness, streamlined stock preparation layouts with lower power consumption, and high-efficiency steel dryers that contribute to measurable steam savings. In short, optimization and innovation are ongoing, driven by a strong R&D foundation.

PD : Which market segments does JMC primarily serve?

RP : JMC caters to a broad spectrum of the industry, including Kraft Paper, Packaging Grades, Testliner, Fluting, White Top Linerboard, Duplex and Triplex Board, Specialty Papers such as wrapping and absorbent grades, and MG papers. For Tissue, we work closely with our Technology Partner Kawanoe Zoki of Japan to deliver advanced, high-speed tissue solutions. This diversified portfolio allows us to meet the needs of both domestic and global markets.

PD : How has market demand influenced JMC’s growth?

RP : Market demand—both Domestic and International—has been a major catalyst for JMC’s evolution. International customers have pushed us towards High-speed, Wide-Deckle Paper Machines that incorporate Advanced Automation, robust mechanical design, and Energy Efficiencies.

Meanwhile, Indian mills have inspired us to create Cost-effective, Durable, and Flexible solutions that perform reliably under local conditions and raw material variations.

PD : What are the key innovations JMC has introduced recently?

RP : Our recent innovations include major advancements in Heavy Fabrication, enabling us to build large, high-speed machines comparable to global standards. We have also developed Integrated pulp-and-paper turnkey solutions, Digital Monitoring tools, and advanced automation packages. However, our most transformative development is MILLMIND—JMC’s AI-driven digital intelligence platform for mills.

PD : How does JMC manage such a wide range of services and maintain integrated project execution?

RP : We operate through a well-defined vertical structure that includes specialized teams for Design, Fabrication, Machining, Quality Inspection, Project Management, Automation, Electricals, and Site Commissioning. This ensures that every stage of the project—from conceptualization to installation—is managed with precision and accountability. With over two decades of experience in Turnkey Execution, we have refined our internal processes to deliver Consistent Quality, Timely Completion, and Long-term Support. Our ability to coordinate cross-functional teams is one of our key strengths as an EPC partner.

PD : What key challenges has JMC faced, and what lessons have been learned?

RP : International projects have taught us the Importance of Cultural Awareness, Documentation Skills, Local Compliance, and Strong Logistical Planning. Heavy fabrication for large machines has reinforced the need for world-class tolerances and stringent quality controls.

Customization for each mill has shown us that Flexibility, Close Customer Engagement, and Adaptive Engineering are essential. These experiences have strengthened our reputation as a Reliable, Globally Competent Partner.

PD : How has the Indian paper machinery industry evolved over the last 20 years?

RP : The Indian industry has made remarkable progress—from low-speed 50–100 TPD machines in the early 2000s to today’s Automated, 300–500 TPD high-speed lines. Developments in Metallurgy, CNC machining, Engineering Software, and Process Design have elevated Indian machinery to international standards. Advanced Press sections, Dilution-controlled Headboxes, and Efficient Stock Preparation Systems have become common. The Adoption of Automation, IoT systems, and Digital Tools has further transformed performance and sustainability.

PD : How does JMC ensure it remains globally competitive?

RP : We adhere to Global Design Standards, maintain Strict Fabrication SOPs, use High-Grade Materials, and adopt Advanced Testing Methods. Collaborations with Japanese & European Experts strengthen our technical base. Additionally, we maintain a Global Supplier Network for Critical Components, ensuring our machines meet International Expectations for Durability, Performance, and Efficiency. PD : What growth do you foresee in the Indian paper industry over the next decade? RP : India’s paper and packaging sector is poised for significant expansion driven by e-Commerce, Food Delivery, Sustainable Packaging Demand, and Hygiene Awareness. Kraft paper, duplex board, tissue, and specialty grades will see Substantial Increases in demand. Waste paper-based mills, Agro-residue-based mills, and Eco-friendly manufacturing solutions will dominate the next decade.

PD : What growth do you foresee in the Indian paper industry over the next decade?

RP : India’s paper and packaging sector is poised for significant expansion driven by e-Commerce, Food Delivery, Sustainable Packaging Demand, and Hygiene Awareness. Kraft paper, duplex board, tissue, and specialty grades will see Substantial Increases in demand. Waste paper-based mills, Agro-residue-based mills, and Eco-friendly manufacturing solutions will dominate the next decade.

PD : How is JMC preparing for this future growth?

RP : We are expanding our Manufacturing Capacity at Sanand, enhancing Technical Manpower, Strengthening Global Partnerships, investing in Heavy Fabrication Infrastructure, and introducing advanced digital tools like MILLMIND. Our objective is to meet the Increasing Global Demand with high-quality, energy-efficient, and technologically advanced machinery.

PD : What challenges do you foresee, and how is JMC addressing them?

RP : Key challenges include Raw Material Fluctuations, Increasing Energy & Water Costs, and Rising Competition. JMC is addressing these by developing more Energy-Efficient Machines, optimizing Process Layouts, Enhancing Automation, and Maintaining Global Quality Standards to stay competitive in export markets.

PD : What are some notable international projects executed by JMC?

RP : JMC has successfully delivered major turnkey projects in Uganda, Ethiopia, Kenya, Ivory Coast, South Africa, Bangladesh, Canada, and Mexico—including the 200 TPD Balaji JMC Paper Mill. These projects reflect our technical expertise, global trust, and ability to execute large-scale international assignments with consistent performance.

PD : Has the company or leadership received any recent recognitions?

RP : JMC has earned multiple awards and recognitions from Customers and International Partners for machine performance, efficient project execution, and innovation. The company maintains ISO certifications and is known for its high standards of quality and reliability. A recent milestone of personal significance was being awarded the Doctor of Letters (D.Litt. – Honoris Causa) by SAGE University, Indore.