- Press felt measurements are highly relevant for the operation of a paper machine. However, the safety and health of the employees must not be subordinated for the measurement.

- With the help of the self-driving ProTect NG, important criteria of press felt performance – such as water content, water absorption capacity and felt tension – are measured and shown in a 3D diagnosis.

- The measurements can be used for fault diagnosis, prediction of remaining running time and optimization of the felt design.

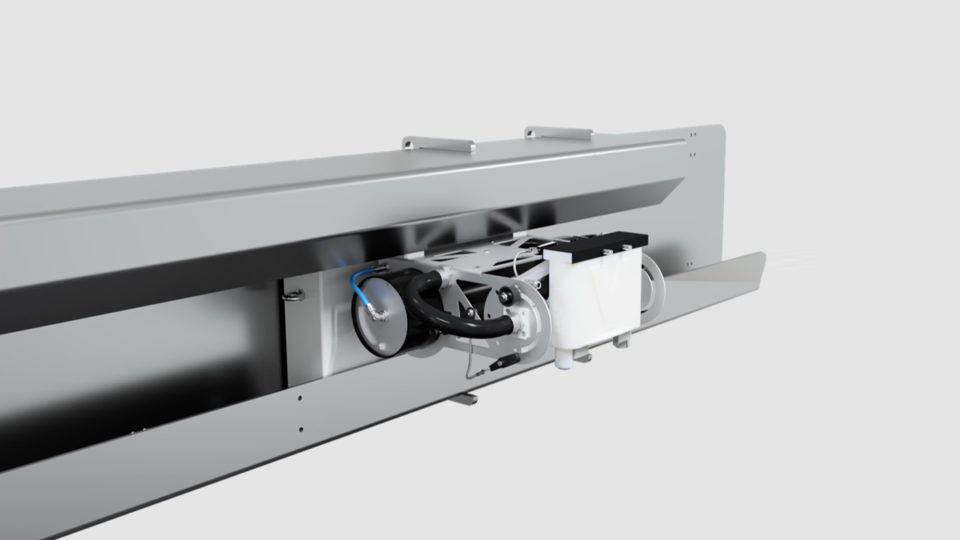

Low effort: ProTect is a carriage and rail system that picks up the felt measuring device brought along and moves it across the machine. Supply and data lines are redundant.

HEIDENHEIM, GERMANY. When measuring press felts manually, there is often a risk of jamming, tripping and slipping. At some positions, the employee is additionally exposed to enormous heat and the constant danger of a felt break also represents a significant, permanent safety risk. Yet, the measurement of felts is an important component in the papermaking process. The automated measurement with Voith´s ProTect NG (Next Generation) therefore offers an excellent alternative to determine the important felt data without risk.

The ProTect system consists of an autonomous carriage and one or more fixed rails (traverses). The user waits on the runway during the measurement and thus no longer remains in the hazardous area. A carriage can be used in different paper machines. It does not matter how wide the machines are, and whether the carriage has to run to the left or to the right.

The new generation of the ProTect NG carriage also offers programmable measuring cycles, self-diagnosis and remote service access. Furthermore, the carriage speed can be reduced to the point where 3D mapping travel is possible. The traverses can be installed in almost any position, even those that are difficult to access. No water, electricity or compressed air connection is required at the actual measuring points, as the ProTect NG carriage is a “self-supplier”. Only the charging station needs a 110/220V power connection – and in the best case a water connection to fill the tank.